ARCtecno

Engineering / Production:

St. Alba Rosa, 50

Olot, Girona – 17800

Cell.: 972280650

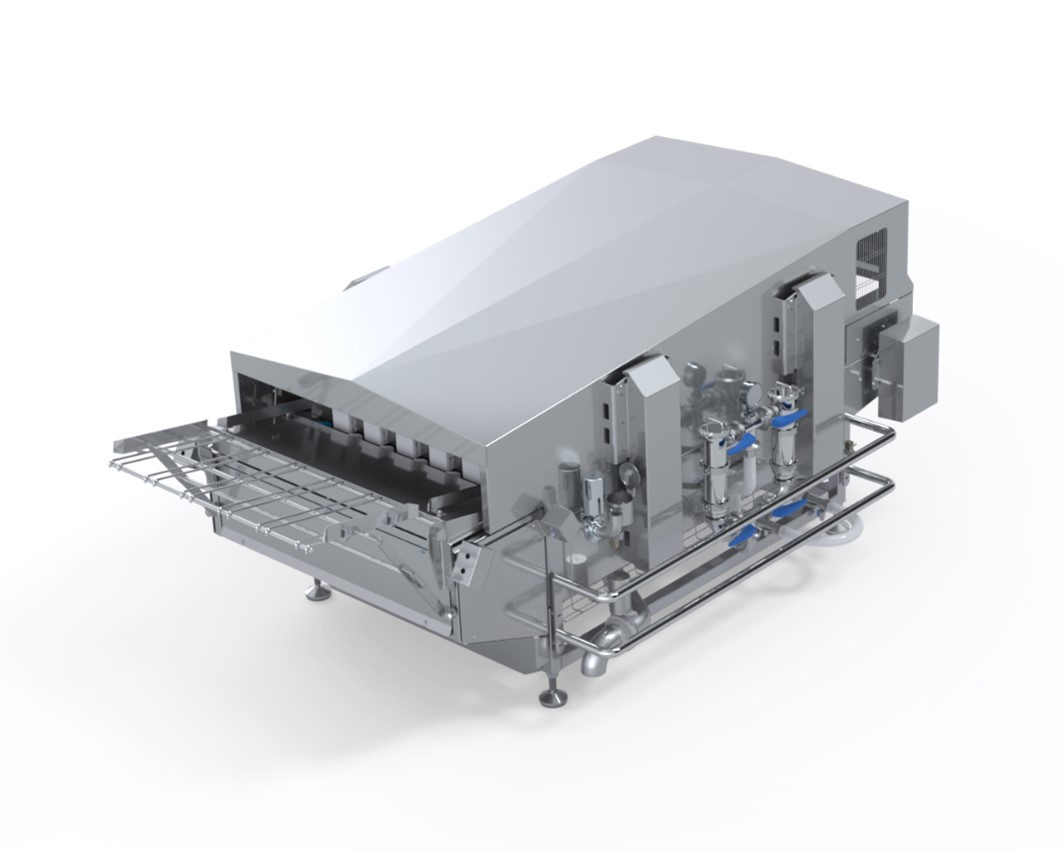

The Hydrator RMPE1200 is co-dependent with the Peeling Machine MPE1200. Together they form a high-performance peeling line to remove the casings from the cured sausage.

The Hydrator sprays water on the cured sausage bars before being peeled by the automatic Peeler.

The useful length inside the hydrator is 2000 mm. Its capacity may vary depending on the calibers of the sausages. The standard measures between centers are 100 mm to work with 22 pieces and 150 mm between centers for 14 pieces.

The high-performance hydrator is equipped with a automatic water management system.

It reuses water by continuous recirculation through a double filter and has an automatic self-filling system with solenoid valves, as well as water level and temperature management.

ARCtecno

Engineering / Production:

St. Alba Rosa, 50

Olot, Girona – 17800

Cell.: 972280650