ARCtecno

Engineering / Production:

St. Alba Rosa, 50

Olot, Girona – 17800

Cell.: 972280650

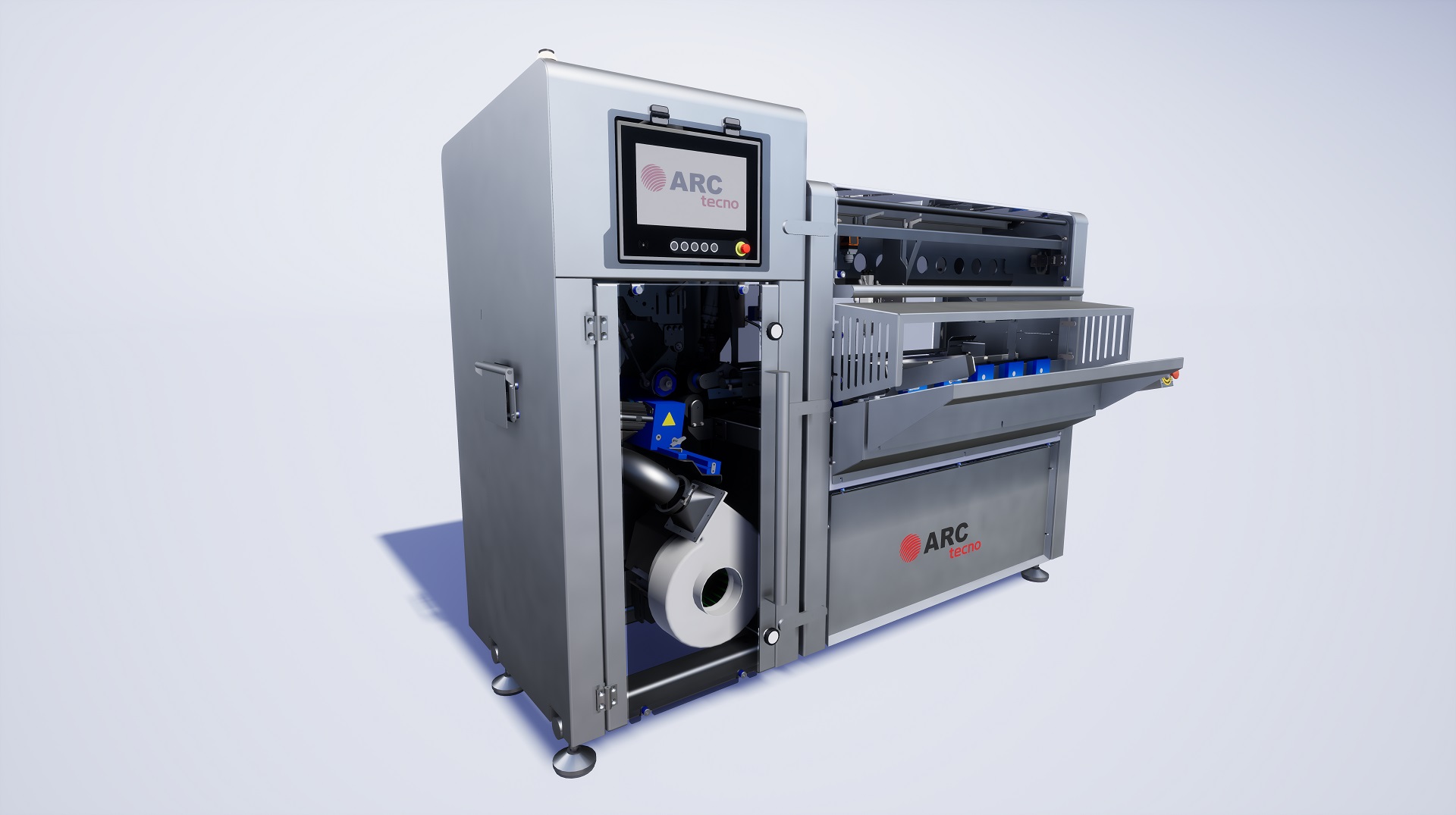

The compact peeler MPEC1200 it is designed to remove the casing from the cured sausage bars (cellulose, collagen, fibrous, etc....) before slicing them.

The cured sausages peeler can work with a hydrator unit which softens the casigns of products such as pork loin, chorizo, salami and pepperoni logs before peeling them.

The Compact Machine can also work without a hydrator unit if your product do not require hydration before being peeled.

The MPEC1200 has a productive capacity of up to 600 pieces per hour, depending on the cured sausages and the casings; and a standard length to work with products of 500 mm as a minimum up to 1,200 mm. This dimension can be modified according to the length of your product.

ARCtecno

Engineering / Production:

St. Alba Rosa, 50

Olot, Girona – 17800

Cell.: 972280650